|

|

|

|

|

Conveyor

BATCH CODING EQUIPMENTS

|

|

|

Conveyors

Our esteemed clients can avail from us the most preferred

range of Conveyor Machine. This Belt Conveyor Machine works as

feeding and conveying equipment, used for transferring nature

rubber. The machine comprises of Selection Reducer, couple of

chain wheels & chains principal wheel and a belt. It works in

a very systematic and convenient manner. In order to feed the

blocks, one of the chain wheel carries the other to work

together when the Select Reduce move. The Principal Wheel is

made to do circumgyratetion with the belt. This machine is

sourced from the state of Gujarat in India. Our esteemed clients can avail from us the most preferred

range of Conveyor Machine. This Belt Conveyor Machine works as

feeding and conveying equipment, used for transferring nature

rubber. The machine comprises of Selection Reducer, couple of

chain wheels & chains principal wheel and a belt. It works in

a very systematic and convenient manner. In order to feed the

blocks, one of the chain wheel carries the other to work

together when the Select Reduce move. The Principal Wheel is

made to do circumgyratetion with the belt. This machine is

sourced from the state of Gujarat in India.

SPECIFICATIONS:

-

S.S. & M.S. VARIABLE / FIX SPEED BELT-CONVEYOR WITH ADJUSTABLE

GUIDE.

-

Speed: Variable Speed with VFD, Standard Motor Gear Box with

Power Regulator & On/ Off Switch.

Note: Other Specifications Are As Above.

EXTRA FEATURES:

-

Vibration less Motion Which Gives the Best Coding Thrue out

The Length.

-

Extra Feeder Plate for Resting the Bunch of Product and Sloper Output Plate for Product Easy Outward.

-

Free Attachment Facility For Your Encoder Of The Inkjet

Machine On Our Roller Shaft With Suitable Design.

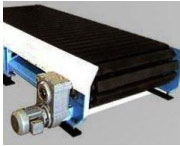

Belt Conveyor

We specialize in the manufacture of Belt Conveyors and are one

of best manufacturer and exporter of belt conveyors in India,

which you can avail at CONPAPTEX at competitive price with

best quality. We have a huge range of Belt Conveyors, which

are in demand due to its robust construction and tensile

strength. Belt Conveyors are fabricated with superior quality

raw materials and standard bought out items such as Gear Box,

Motors, Belts and accessories, to give high strength and

durability to conveyors system. We specialize in the manufacture of Belt Conveyors and are one

of best manufacturer and exporter of belt conveyors in India,

which you can avail at CONPAPTEX at competitive price with

best quality. We have a huge range of Belt Conveyors, which

are in demand due to its robust construction and tensile

strength. Belt Conveyors are fabricated with superior quality

raw materials and standard bought out items such as Gear Box,

Motors, Belts and accessories, to give high strength and

durability to conveyors system.

CONPAPTEX provide best Belt conveyors for production flow

line. Belt conveyors are employed for conveying various bulk

and unit loads along horizontal or slightly inclined paths and

for transporting articles between various operations and are

the main means of mechanical transport. Belt conveyors make

material handling easy and cost effective as it improves

production process and save from human error.

Belt Conveyor Benefits.

CONPAPTEX supply self tracking belt technology, smooth product

movements, and supplied standard with Geared motor or Drum

roller drive. We can customize your equipment to suit your

requirements. The belt can be on rollers, a link belt or slide

bed. This style is simple but is an overly productive

conveyor.

Belt Conveyors has many benefits including:

-

Self Tracking Belts - Our design provides for the belt to be

self tracking thus eliminating countless maintenance issues

for the end user.

-

Cost Effective. Because in house manufacturing our machines

provide excellent value for money.

-

Versatility in Design - Tailor made design solution

available at no extra cost.

-

Smooth and Quiet Transport - this conveyor will move

materials will ease. Its simplistic style is quiet and smooth,

moving products to the required destination.

-

Irregular Product Movement - designed for those products

that cannot easily be moved by other machine styles. Products

like sacks, bags and raw food products can be moved safely,

making it convenient transportation.

-

All levels movement - Consider safe solution for materials

handling. It offers a simple height incline and decline;

ensuring products get safety to their area.

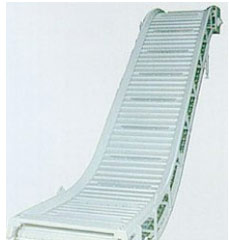

Roller Conveyors

CONPAPTEX offer a range of advanced technology Roller

Conveyors. Roller conveyors are the proper choice when you

need to side load, push off, accumulate a product or adjust

pressure on carrying rollers. Roller conveyor types are chain

driven, belt driven, line shaft driven, accumulation, or

non-powered (gravity). Using roller conveyors instead of

slider bed conveyors adds versatility to the type of

transfers, diverters and stops that can be used in a system.

Rollers are available in mild steel, galvanized, plastic or

stainless steel. CONPAPTEX offer a range of advanced technology Roller

Conveyors. Roller conveyors are the proper choice when you

need to side load, push off, accumulate a product or adjust

pressure on carrying rollers. Roller conveyor types are chain

driven, belt driven, line shaft driven, accumulation, or

non-powered (gravity). Using roller conveyors instead of

slider bed conveyors adds versatility to the type of

transfers, diverters and stops that can be used in a system.

Rollers are available in mild steel, galvanized, plastic or

stainless steel.

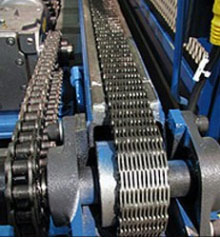

Chain Conveyors

We, CONPAPTEX are now a well reckoned manufacturer and

exporter, amidst the chain conveyor manufacturers in India. We

offer all types of chain conveyors at most competitive price

without compromising quality. We, CONPAPTEX are now a well reckoned manufacturer and

exporter, amidst the chain conveyor manufacturers in India. We

offer all types of chain conveyors at most competitive price

without compromising quality.

CPT Chain conveyors system is highly valued amongst clients

for its unending features like:

-

Heavy duty conveyor frame

-

Heavy duty adjustable legs

-

Single & Double Chain

-

Head and Center Drive models

-

Constant and variable speed packages

-

100 - 2000 mm widths (higher on request)

-

300 - 10,000 mm lengths (higher on request)

-

Available as inclined conveyors

CONPAPTEX, expertise in offering a robust and precision

engineered range of Chain Conveyors, available in singly and

multiple chains. Our multipurpose Chain Conveyors are

manufactured, using latest technology and equipments to serve

you quality, high functionality and user friendly operation.

Chain Conveyors are widely used in automobile industries.

Chain Conveyor Benefits

-

Chain Conveyors allow for multi-directional and flexible

movement of material. Unlike other Conveyors, CONPAPTEX system

works permit horizontal as well as vertical change of

direction. Our parts are manufactured for ultimate durability

and functionality, each designed to enable you to move the

chain in the direction required.

-

Chain Conveyors have multiple benefits for businesses, these

include:

-

Most Adaptable - Objects of any size can be placed on the

Chain Conveyors, which are otherwise difficult to handle and

can be moved up, down, in out and around.

-

Versatile - This machine is used in all types of industries.

-

Direct movement - Products can be moved easily and directly

on the conveyor and transported effectively.

-

Multiple uses - These machines can be used in combination

with other equipment such as Gravity Roller and Powered Roller

Conveyors.

-

Cost Effective -Standardization and simplicity of component

parts, together with complete production tooling mean actual

saving.

Apron Conveyors

Apron Conveyors are used to carry materials and pieces

horizontally and inclined lines. CPT offers Apron conveyors,

which are made of pans with uneven edges to keep a check on

material loss. CONPAPTEX offers Apron Conveyors which are

flexible for adaptation to lifting loads from hoppers bins.

Apron Conveyors can be regulated by adjustment of a sticker

plate at the entrance point. CONPAPTEX have a heavy handle,

which can handle abrasive and hot material. Apron Conveyors

are capable of handling material up to 2000 per hour and does

not cause noise pollution while carrying the material. Apron Conveyors are used to carry materials and pieces

horizontally and inclined lines. CPT offers Apron conveyors,

which are made of pans with uneven edges to keep a check on

material loss. CONPAPTEX offers Apron Conveyors which are

flexible for adaptation to lifting loads from hoppers bins.

Apron Conveyors can be regulated by adjustment of a sticker

plate at the entrance point. CONPAPTEX have a heavy handle,

which can handle abrasive and hot material. Apron Conveyors

are capable of handling material up to 2000 per hour and does

not cause noise pollution while carrying the material.

Advantages of Apron conveyors.

-

Adjustable - The apron conveyor can be adjusted to any

length by changing the number of plates. Maintenance and

repair are also easier.

-

Easy Maintenance - When a part of the conveyor breaks, the

damaged plates can be removed and replaced instead of the

whole apron conveyor, which saves the operator time and cost.

-

Robust Structure -Apron conveyors made from high grade

steel are useful for handling abrasive materials, such as

rocks and granules. Walls and overlap in the apron plates

ensure minimal material loss, especially when transporting

grains and detritus.

-

Widly Used -Mainly used for industrial purposes, apron

conveyors are made to withstand tremendous weight, heat, and

continuous operation. The conveyor can be treated with special

coatings to achieve a desired surface, such as friction or

elasticity.

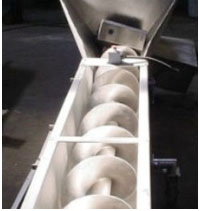

Screw Conveyors

CONPAPTEX offers highly effective Screw conveyors with latest

technology making them accurate at function. Screw conveyors

are bulk material transporting devices capable of handling

great variety of materials, which has relatively good flow

ability. CONPAPTEX have become one of the reliable

manufacturer and exporter of Screw Conveyors that are known

for conveying sand crescent or any other material in powder or

cake form. This characteristic is important in screw conveyors

operation as the screw helix mounted on a central pipe or

shaft, rotate within a fix trough or tube pushes the material

in the radial clearance between the helix and trough and

causing the material to tumble upon itself as the moving face

of the helical flight tends to lift the material. CONPAPTEX

provide Screw Conveyors with elegant design and delivers best

performance in complex conditions of temperatures and

pressures. You all are free to call on us and avail Screw CONPAPTEX offers highly effective Screw conveyors with latest

technology making them accurate at function. Screw conveyors

are bulk material transporting devices capable of handling

great variety of materials, which has relatively good flow

ability. CONPAPTEX have become one of the reliable

manufacturer and exporter of Screw Conveyors that are known

for conveying sand crescent or any other material in powder or

cake form. This characteristic is important in screw conveyors

operation as the screw helix mounted on a central pipe or

shaft, rotate within a fix trough or tube pushes the material

in the radial clearance between the helix and trough and

causing the material to tumble upon itself as the moving face

of the helical flight tends to lift the material. CONPAPTEX

provide Screw Conveyors with elegant design and delivers best

performance in complex conditions of temperatures and

pressures. You all are free to call on us and avail Screw

Slat Conveyors

CONPAPTEX are recognized as one of the outstanding

manufacturer and exporter of Slat Conveyors, as we offer Slat

Conveyor having one or more endless chains to prevent

overlapping and interlocking spaced slats. They are similar to

modular belts in there versatility and use. They are able to

transfer product around bends using a single drive. Slat belt

conveyors however tend to be used in narrow accumulation

applications such as bottling or engineering where single lane

product transfer is required. CONPAPTEX are recognized as one of the outstanding

manufacturer and exporter of Slat Conveyors, as we offer Slat

Conveyor having one or more endless chains to prevent

overlapping and interlocking spaced slats. They are similar to

modular belts in there versatility and use. They are able to

transfer product around bends using a single drive. Slat belt

conveyors however tend to be used in narrow accumulation

applications such as bottling or engineering where single lane

product transfer is required.

CONPAPTEX, produce both a standard range and bespoke range of

Slat Belt Conveyors, fully designed manufactured in house from

our facilities in Noida encompassing the widest range of

applications and environments.

Key Features

-

Available in Powder Coated Steel and Stainless Steel

-

Configurations include horizontal straight, curved and multi

lane

-

Pharmaceutical and wash down food grade available as

standard

-

Common simple and robust construction

-

All widths and lengths both as standard and customer

specific sizes

-

All loads and configuration of product ideally suited to

accumulation and curved applications

-

Many drive configurations including shaft mounted motor,

chain driven head drive and under slung drives available as

standard

-

Accessories include many control options, large range of

guide systems, supports and mobile frames

-

Common applications include, bottling, automotive, food and

pharmaceutical.

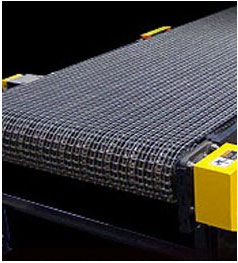

Wire Mesh Conveyors

CONPAPTEX are one of the prominent Manufacturer and Exporter

of the cutting edge technology of Wire Mesh Conveyors. Wire

Mesh belt conveyors are mainly used for high temperature

applications such as transferring products through tempering

or cooling ovens or when handling hot product. Belts are

usually made from either steel or stainless steel with varying

degrees of weave and pitch. CONPAPTEX are one of the prominent Manufacturer and Exporter

of the cutting edge technology of Wire Mesh Conveyors. Wire

Mesh belt conveyors are mainly used for high temperature

applications such as transferring products through tempering

or cooling ovens or when handling hot product. Belts are

usually made from either steel or stainless steel with varying

degrees of weave and pitch.

CONPAPTEX, produce both a standard range and bespoke range of

Mesh Belt Conveyors, fully designed manufactured in house from

our facilities in Noida encompassing the widest range of

applications and environments.

Key Features

-

Available in Powder Coated Steel and Stainless Steel

-

Common simple and robust construction

-

All widths and lengths both as standard and customer

specific sizes

-

All loads and configuration of product ideally suited to hot

products or were air flow through the conveyor is essential

-

Many drive configurations including shaft mounted motor and

chain driven head drive available as standard

-

Accessories include many control options, large range of

guide systems, supports and mobile frames

-

Large Temperature range available both cold and hot

-

Applications include swarf removal, cooling conveyors,

ovens, recycling, elevators and press works

|

|

|

|

|

|

|

|

|

|