|

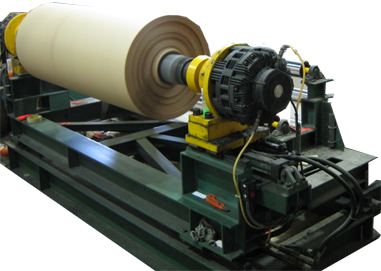

Unwind guiding with tension control (pay

off reel system)

Unwind with edge / line guiding and tension control

Controlled unwind guiding

Description:

Standard adapter bases consist of a stationary floor-mounted

frame or plate, a four unit, standard bearing and support

system, and a moving frame or plate. A heavy duty servo

cylinder is mounted between the frames and the bearings. The

servo cylinder moves the upper adapter base plate back and

forth in response to hydraulic signals from the power unit. The CON-PAP-TEX adapter base is designed for use in applications where the unwind or rewind stand must be shiftable. Standard adapter bases consist of a stationary floor-mounted

frame or plate, a four unit, standard bearing and support

system, and a moving frame or plate. A heavy duty servo

cylinder is mounted between the frames and the bearings. The

servo cylinder moves the upper adapter base plate back and

forth in response to hydraulic signals from the power unit. The CON-PAP-TEX adapter base is designed for use in applications where the unwind or rewind stand must be shiftable.

Standard adapter base assembly consists of stationery mounted

frame, which adopts the existing unwind / rewind stand with

shaft and breaks. In the unwind guide, the idler rollers are

attached to moving frame before fixed detectors to stabilize

web & idle for slitter machines. In the winder guide, the

sensor is attached to the moving frame after fixed idler

rollers, with sufficient wrap to get perfect winding of

material. We can make special kind of rewinding structure

where motors also move along with rewinding rolls.

Applications:

The CON-PAP-TEX adapter base is designed for use in

applications where the unwind or rewind stand must be shift

able. By fitting the adapter base under the stand, a simple

and economical installation is obtained. Because of the

relatively high mass of the unwind or rewind rolls, its use

is most often found in applications. Where response time can

be relatively slow and where accuracies are not overly

critical.

In

Rewind guide the detector is attached to the moving frame

before fixed idler with sufficient warp to stabilize Web.

In

Unwind guide the idler roller attached on moving frame before

the fixed detector to stabilize the Web.

Unwinding:

If

the material wound is irregular, this system guide the edge

position and let it regularly into the subsequent process.

The idler roll moves with the unwinding reel stand.

v

Mount the

detector fixed and as close to the idler roll as possible.

v

The leaving

web formed a angle at the deflector roll should more than

30-. if not possible, apply a pinhole added. The important,

do not allow the web slip on this roll. The distance between

two rolls should be more than the maximum width of the web.

|